Description

In petroleum and natural gas extraction, a Christmas tree, or “tree,” is an assembly of a multi-valved structure consisting of valves, pipe spools, and fittings used to control the flow of oil from the well. The shape of the wellhead structure with valves looks like a pine tree, so the wellhead is called a “Christmas tree”. The Christmas Tree is connected to the top of the tubing and cemented to the top of the casing. These valves regulate pressure, control flow, and allow access to the wellbore when further completion work is required. From the outlet valve of the Christmas Tree, the flow can be connected to a distribution network of pipelines and tanks to distribute the product to refineries, natural gas compressor stations, or oil export terminals.

The Christmas tree consists of an assembly of a gate valve that controls the flow of hydrocarbons. It may consist of individual valves bolted together, or it may feature a cast or forged steel solid block into which the valve chests are machined. Occasionally it is a combination of the two. In all cases, the valve seats and gates are removable for replacement or repair

The primary function of a Christmas tree is to manage the flow of oil and gas from the well. It serves several key purposes:

In producing wells, injection of chemicals, alcohols, or oil distillates to prevent or solve production problems (such as blockages) may be used.

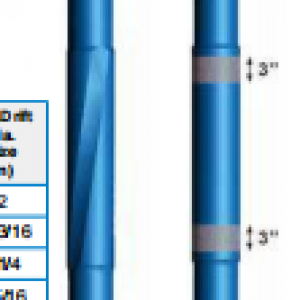

A typical Christmas tree is composed of a master gate valve, a pressure gauge, a wing valve, a swab valve, and a choke as shown in Fig. 1. The Christmas tree may also have a number of check valves.

At the bottom, we find the casing head and casing hangers. The casing will be screwed, bolted, or welded to the hanger. Several valves and plugs will normally be fitted to give access to the casing. This will permit the casing to be opened, closed, bled down, and, in some cases, allow the flowing well to be produced through the casing as well as the tubing. The valve can be used to determine leaks in the casing, tubing, or packer, and will also be used for lift gas injection into the casing.

The tubing hanger (also called a donut) is used to position the tubing correctly in the well. Sealing also allows Christmas tree removal with pressure in the casing.

Our wellhead experience includes:

What is a Christmas tree?

The Function of a Christmas Tree

Components of a Christmas Tree

KQ Series Sulfide Resistant Oil/Gas Production Wellhead

KQ Series Sulfide-Resistant Oil/Gas Production Wellhead is designed and manufactured according to SY5-93 and API spec 6A.All pressure bearing parts and flanges are made of quality alloy steel forgings, NDT and special heat treated to guarantee safety, providing the wellhead with excellent sulfide-resistant property.

The KQ series wellhead equipment consists of bottom flange, upper flange, tubing head, gate valve, small cross, stop valve, and meter, etc.

Specifications for Products

|

Model |

|

|

|

|

|

|

|

|

|

Working |

|

|

|

|

|

|

|

|

|

Nominal |

|

|

|

|

|

|

|

|

|

Working |

|

|||||||

|

|

|

|||||||

|

|

|

|

PFF65-35 |

PFF65-60 |

PFF65-70 |

PFF78-70 |

PFF65-105 |

PFF78-105 |

|

|

|

|

PFF65-35 |

PFF65-60 |

PFF65-70 |

PFF78-70 |

PFF65-105 |

PFF78-105 |

|

By-pass |

|

|

PFF65-35 |

PFF65-60 |

PFF65-70 |

PFF78-70 |

PFF65-105 |

PFF78-1 |